From AnderweltOnline.com

By Peter Haisenko

The B 737 MAX is a faulty design from the beginning. Anyone who knows anything about aerodynamics will recognize it immediately if they only look at the aircraft.

The example of the Boeing 737 and especially the latest development stage MAX 8/9 shows how fatal it is when it is not engineers who make the decisions, but merchants. No engineer in his right mind would have built the 737 MAX like this if he hadn’t been forced to do so by greedy managers. The nearly 400 deaths in two crashes were caused by Boeing’s board of directors, as well as the threatening bankruptcy of the entire company.

Boeing’s B 737 was a crutch right from the start. When Boeing planned the B 737-100 in the early 1960s, a seat configuration of 2/3 was planned, as with the DC 9. Lufthansa, as the largest first customer for the “City-Jet”, wanted a 3/3 version, as with the B 727 and the B 707. However, the construction was already advanced and so the tinkering began in order to save costs. Boeing simply left the already planned cockpit as narrow as it was and so the pilots still have to squeeze themselves into a cockpit for all versions of the 737 for which you actually need a shoehorn to get in. But this mini cockpit is of course lighter than an ergonomically sensible one and so the merchants are happy.

But that wasn’t the only cost-saving (lazy) compromise.

In order to save costs, Boeing has designed flying crutches

The nose and main landing gear were not designed for the now larger hull from the beginning. Our flight engineers told me that during their studies of aeronautical engineering in the 1960s the nose landing gear of the 737 was presented to them as a negative example of how not to do it. Nevertheless, the B 737-100 became a successful model, which was mainly due to a lack of competitor models. In the 1970s, the B 737 was modernised for the first time with the model B 737-200. The more powerful JT-8 engines were still small in size and fitted under the low wings. Boeing responded to the contemporary requirements for bad weather conditions with an autopilot construction that was a crutch from the beginning but is still used in all B 737 models today.

This led, for example, to the crash of the “Fly Dubai” in Rostow in April 2016.

Boeing introduced the 737-300 model in the mid-1980s. It had a “glass cockpit” like the Airbus A 310 (with screens instead of a “clock shop”) and modern engines with a large front rotor. Boeing would have had to carry out a new design already here, because the engines no longer fit under the low wings. In order to save the costs for a new construction and above all the complex approvals for it, the next crutch came. The engine was placed a bit higher and further forward and the intake of the engine was flattened at the bottom so that it wasn’t too close to the ground and so absorbed every stone from the ground, which would have destroyed the engine.

In the further years Boeing has “drilled” the 737 more and more with the models up to -800. Boeing has not changed anything about the basic construction from the 1960’s with its deficits. It is simply inexpensive for the production to continue using already certified units.

At the end of the 1980s Airbus introduced the A 320, which was a completely new design and Airbus set standards in terms of flight guidance systems and design. The A 320 became a direct and successful competitor for the B 737. Boeing came under pressure, but was able to win more customers for its crutch 737 because of the favourable purchase price. This was also because Airbus could not deliver as many aircraft as the worldwide demand was. Here we are faced with a fundamental problem in international aviation: enormous growth, especially in Asia and Africa. There is a lack of qualified junior pilots and mechanics with sufficient experience. Airbus had anticipated this problem and designed the A 320’s flight guidance systems to provide meaningful support for even less experienced pilots. Boeing is trying to catch up, but is not able to reach the A 320, which was designed more cleverly from the start. Airbus has once again set new standards with the A 320-neo.

Now we have to look at the markets for this class of aircraft. They are not just now in areas where other qualities are desired than in Europe. Even in the USA, airlines do not have the capacity to land in extremely poor visibility. To date, there are only a few airports in the USA that offer the ground-based conditions for a landing according to “Category III”, i.e. for visibility below 100 metres. These conditions are expensive, on the ground and in the air. In Africa or Southeast Asia they practically do not exist at all, simply because the demand is not there. This also explains why Boeing never set about bringing its crutch from an autopilot to a decent level. An estimated 90 percent of customers have no need.

With high oil prices, the demand for fuel-saving models has increased. Airbus has once again set standards with the A 320-neo and its particularly efficient engines. Boeing was in a tight spot. But the super engines of the A 320 simply did not fit under the wings of the old B 737 anymore. But instead of finally constructing a completely new model, the Boeing merchants decided to build the ultimate crutch beyond all aerodynamic rules. The engines that were too big for the 737 were moved even further forward and upwards.

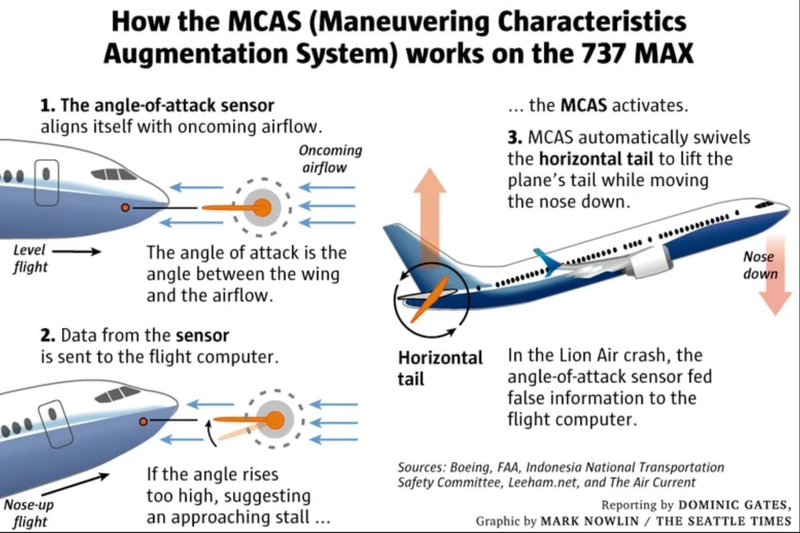

During the first test flights it turned out that the physics cannot be outwitted so simply. The airflow of the engine now passed directly under the wing, which must have several negative effects. Once the lift is influenced negatively, but the biggest problems were in the extreme slow flight, that is shortly before the stall, which can lead to a crash.

In this situation, the airflow from the engine of the 737 MAX is located under the entire lower outer wing, which puts the aircraft in an uncontrollable state. Instead of finally redesigning the aircraft, Boeing’s managers opted for the worst crutch: they had a system installed that takes full control of the aircraft at this limit. If a sensor, and only one sensor, detects this limit, the attached computer causes the aircraft to move the tailplane trim to “nose down”. That wouldn’t be wrong in principle, but it would overshoot the mark.

The fact that this deadly system has no control system, which as such should not occur in aviation, has now proved fatal twice. This means that if this single sensor gives an error message, pilots have little chance of preventing their aircraft from flying into the ground without being pointed. The hole in Ethiopia’s ground speaks for itself.

It’s not the engineers who are responsible, it’s the managers.

Now you should know that the tailplane trim of all smaller Boeing models has always been a prone crutch. It’s a motor-spindle unit that tends to “run away” or jump out and jam if a relay fault occurs. For this reason there was a prominently placed emergency switch on the B 727 with which the trim motor could be switched off. This was practiced in the simulator. The newer 737 models no longer have this emergency shutdown device.

So the pilots can’t switch off the trim motor and save the plane even if they recognized the error. They would have to switch off the entire busbar on which the trim motor hangs. But this would shut down other elementary systems and it is a process that cannot be carried out in a fraction of a second. So if the only sensor for the angle of attack sends a wrong signal to the only computer, then this aircraft can no longer be saved, at least if it flies at low altitude.

The B 737 MAX is a faulty design right from the start. Anyone who knows anything about aerodynamics will recognize it immediately if he only looks at the aircraft. It forms the tip of a series of crutch constructions that run through the entire history of B 737 development. It is not engineers who are responsible for this, but the managers who force the engineers to build crutches against their better judgement.

The fact that this better knowledge is actually happening again is proven by the fact that there is an e-mail from summer 2018, i.e. before the first crash, in which Boeing employees already document what effects this design error can have. Boeing’s board of directors did not react and accepted so approvingly that exactly what happened twice within a few months happens – with almost 400 dead.

Ethiopia trusts neither the manufacturer, nor the US licensing authority FAA

In addition to Boeing’s managers, the heads of the FAA, the American regulatory authority, must of course also be called to account. They certified the airworthiness of the 737 MAX, although they had to know what kind of crutch it was. So it is not surprising that the FAA was the last to ban the 737 MAX from flying. It is already a unique event in the history of aviation that individual countries all over the world first had to rush ahead with flight bans, before the authority actually responsible for them desists to do so. However, this was preceded by a unique process.

It was not the FAA or the manufacturer Boeing that banned the 737 MAX from flying in the USA. It was Donald Trump who pulled the emergency brake with a decree. After that, the FAA and Boeing could no longer help but to follow the step that would have been due by summer 2018 at the latest. Also interesting is the next procedure, which is again unique: Ethiopia did not leave the accident investigation to the FAA or Boeing.

Contrary to standard procedures, the investigation was transferred to the French BEA and the flight recorder was sent to Paris for investigation. This is almost a declaration of war on the American aircraft industry, but at least a demonstration of how little trust remains in the integrity of American institutions. This is probably also a consequence of the fact that in expert circles a large number of deliberately falsified results are known which the American authorities have delivered on aircraft accidents. Let us just think of the TWA 600, which was downed by an American rocket and which was concealed from the public and even from us pilots with all its criminal methods.

The history of the B 737 MAX and all 737 models shows the state of the USA and its (aircraft) industry. For even short-term profit, all rules are set aside that have been developed for decades out of bitter necessity. What role do a few hundred deaths play when it comes to saving profit? The FAA itself is obviously corrupted through and through and here comes the next interesting aspect.

Donald Trump obviously knows this, because he wanted to put his personal chief pilot on the FAA’s executive chair, but this met with massive resistance. There we have the next point, why the American establishment hates Trump so much. He obviously wants to dry up the swamp at all levels. If he had his way, it’s not unlikely that the 737 MAX in this configuration wouldn’t have been approved and 400 people wouldn’t have been crushed. Another piquant detail is that from the beginning warnings came from Russia regarding the airworthiness of the 737 MAX.

Turbo-capitalism cannot persist in the long run

The disasters with the B 737 MAX have put the entire aviation industry in great distress. There will also be bottlenecks in Europe in the charter summer of 2019. But for Boeing itself it can mean the end. After all, several hundred copies of the 737 MAX have already been delivered and will probably have to be scrapped, because a simple retrofit with software cannot solve the basic problem of the faulty design. Simply resuming production of the old models of the 737 is no solution. It’s not that simple and who would want to have an airplane that can’t survive next to the A 320 neo?

The 737 MAX case makes it clear that turbo capitalism cannot exist in the long run. The whole world cannot function “sustainably”, and aviation certainly cannot, if only profit is the determining element. Not only the “diesel scandal” shows this, now drastically Boeing.

So what we need is a radical rethink. Capital and its managers and profiteers must be deprived of power and given back to reason and public spirit. This applies not only to the aircraft and car industries, but above all to the pharmaceutical industry, which does not want to heal people at all, but pursues the primary interest of selling more and more medicines to healthy people.

However, in order for an improvement to be possible, and in order to prevent thousands of people from continuing to lose their lives because of profit-seeking, the entire system must be fundamentally overhauled. This must be radical and must not leave out anything that should have been questioned long ago.

In this sense we have developed “The Human Market Economy” from scratch and I don’t think it is excessive to say that exactly this revolutionary system according to Haisenko/von Brunn has the potential to solve all, repeat all, the problems under which humanity suffers under the religious-capitalist dictatorship.

Peter Haisenko was a pilot with Lufthansa and flew for 30 years in worldwide service as a co-pilot and captain. Since 2004 he has worked as a freelance author and journalist. He is the owner and publisher of the online portal www.anderweltonline.com